|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Workers Finish Installing a Bridge Crane in the Silos 1 and 2 Treatment Facility that will be used to Load the Waste Containers for Transportation Off Site.

|

|

Workers are Trained how to Operate the Silo 3 Excavator.

|

|

Workers are Trained to Seal the Soft-Sided Packages that will be used for the Silo 3 Waste.

|

|

Silo 3 Treatment Facility

|

|

Fernald Silo 3 Project - Shipping Preparations

|

|

Work Continues in the Three Product Fill Rooms where the Casks will be Filled Robotically with the K-65 Stabilized Waste.

|

|

Fernald Silo 3 Project - Shipping Preparations

|

|

Fernald Silo 3 Project - Waste Packaging

|

|

|

|

Fernald Silo 3 Project - Shipping Container

|

|

Fernald Silo 3 Project - Waste Retrieval

|

|

|

|

|

|

|

Analytical Lab Decontamination and Demolition Project - An Operating Engineer uses Grapplers to Segregate Demolition Debris that Needs Further Size Reducing from that which can be Immediately Loaded for Transfer to the On-Site Disposal Facility (OSDF).

|

|

An Operating Engineer Loads Building Debris into an Articulation Dump Truck on the Pad of the Lab Building.

|

|

Operating Engineers Topple the Last Section of Plant 8 by Pushing the Structure to the Ground.

|

|

Operating Engineers use Shears to Cut Away Sections of Plant 8.

|

|

Workers Remove Process Piping in the Pilot Plant as Part of the Demolition Process.

|

|

Workers Install Insulation on Piping in the TTA Building.

|

|

Electricians Install Various Sizes of Conduit in the Electrical Room.

|

|

The Bio-Dentrification Tower and Plants 2 and 3 Prior to Demolition.

|

|

Plants 2, 3 and 8 After Demolition.

|

|

The Bio-Dentrification Tower and Plants 2 and 3 After Demolition. Excavation Crews are Now Removing the Below-Grade Portions of the Structures.

|

|

Workers Remove Transite Panels from the Pilot Plant in Preparation for the Demolition of the Concrete Structure.

|

|

Early Demolition Stages of Plants 2, 3 and 8.

|

|

Operating Engineers use Grapplers and Bulldozers to Place and Compact Demolition Debris in Cell 4 of the On-Site Disposal Facility (OSDF).

|

|

Two Crews Work to Remove Waste Material from Pit 2.

|

|

A Supervisor Gives Instructions to an Operating Engineer in Pit 3.

|

|

Fernald's K-65 Silos are Gone.

|

|

The Decontamination and Demolition Project Work Scope Includes the Dismantlement of 259 Former Production Plants, Support Structures and Associated Components.

|

|

A Member of the Waste Acceptance Organization Inspects a Section of Pipe Before Allowing Workers to Move it to the On-Site Disposal Facility (OSDF).

|

|

An Iron Worker Installs Rebar at Valve House 7.

|

|

An Electrician Verifies that One of the Motor Controls that will Operate a Piece of Equipment in the Silos 1 and 2 Treatment Facility Works Correctly.

|

|

A Teamster Places Impacted Material Around Demolition Debris in Cell 4 of the On-Site Disposal Facility.

|

|

Workers Expose the Cell 6 Liner to Prepare the Surface for Attachment to the Cell 7 Liner.

|

|

Plants 2 and 3 Decontamination and Demolition Project - An Operating Engineer Uses a Shear to Size Reduce the Bulk Lime Handling Building.

|

|

A Member of the Quality Assurance Group Watches as a Worker Installs a HEPA Filter at Silo 3.

|

|

A Supervisor and a Member of the Site's Waste Acceptance Organization Watch as Operating Engineers Shear a Section of the Analytical Lab.

|

|

Workers Topple the Bulk Lime Handling Building.

|

|

Silos 1 and 2 Waste Retrieval Project - Iron Workers Assemble Waste Container Handling Equipment.

|

|

Operating Engineers Cover Demolition Debris from the Analytical Laboratory with Impacted Soil in Cell 4 of the On-Site Disposal Facility.

|

|

Fernald Silo 3 Project - Waste Packaging Station

|

|

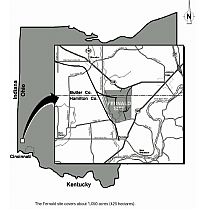

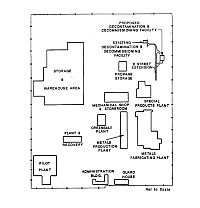

Fermald Map

|

|

Conceptual Image

|

|

Fernald Map

|

|

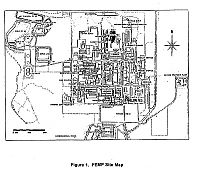

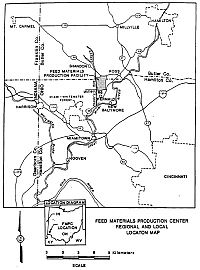

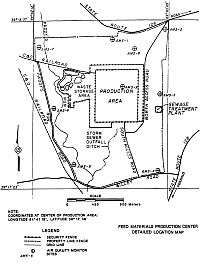

Fernald Environmental Project (FEMP)

|

|

Fernald Environmental Project (FEMP)

|

|

Fernald Environmental Project (FEMP)

|

|

Fernald

|

|

Decontamination & Demolition

|

|

|

|